Chemical Unloading Basics

All personnel involved in bulk unloading of chemicals must be properly trained in general safety awareness, equipment function and emergency shut down, hazardous chemicals, personal protection measures, and security. This course will focus on some basic procedures and safety practices for unloading bulk liquid chemicals from tank trucks and railroad tank cars. Totes and drums will also be discussed.

Request a demoCourse Details

Learning Objectives

• List and describe typical personal protective equipment (PPE) guidelines for chemical unloading • Explain employee ‘right to know’ about the chemicals in the workplace • List basic safety and environmental considerations when unloading liquid chemicals • Identify and describe common equipment used during chemical unloading • Describe precautions that should be taken during vehicle arrival and preparation • List and describe the best practices for hose connection, unloading and hose disconnection • Describe precautions that should be taken during vehicle departure

Specs

| Course Level | Intermediate |

| Languages | English, Polish |

| Compatibility | Audio, Video |

| Based on: | Industry Standards and Best Practices |

Key Questions

What is common PPE for workers unloading chemicals?

Common personal protective equipment, or PPE, required during a chemical unloading process includes: a hard hat, face shield, safety glasses, chemical reistant gloves, fully-body chemical resistant suit, and chemical resistant steel-toe shoes.

What should be inside a spill kit located in chemical unloading and storage areas?

In chemical unloading and storage areas, there should always be an easily accessible spill kit that is fully stocked with items that include: appropriate PPE for spill cleanup or containment, absorbent pads and other materials and equipment for cleaning up small spills, and equipment and materials necessary for containing larger spills.

What is common equipment used for chemical storage, containment, and transfer?

Chemical storage, containment, and transfer equipment is typically made from materials that are compatible with the chemicals in use. Stainless steel is commonly used for tanks and components, while hoses, valves, and pumps must also be specifically selected for chemical compatibility. When unloading flammable liquids, explosion-proof pumps may be required.

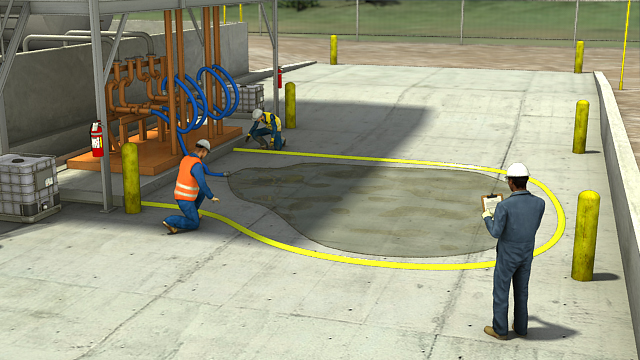

Who should be physically present for chemical unloading?

The designated employee must be physically present with an unobstructed view of unloading operations to continuously monitor the entire unloading process. In some cases, the designated employee may observe the unloading process from a remote location at the facility via video, sensing equipment, or mechanical devices as long as such methods are at least equivalent to being physically present at the unloading location.

Sample Video Transcript

While several federal regulations cover the bulk, loading, and unloading of chemicals, this course will focus on some basic procedures and safety practices for unloading bulk liquid chemicals from tank trucks and railroad tank cars. Totes and drums will be briefly discussed. Be sure to review all necessary requirements for transferring and unloading chemicals from the chemical manufacturer, equipment manufacturer, delivery company, and receiving company to be sure that all regulations and processes are followed. Depending upon the nature and properties of the chemicals being unloaded, there may be additional handling requirements in place by local, state, and federal authorities.

Course Applies To

Demos + Pricing

Learn more about our courses, get pricing, and see our platform.